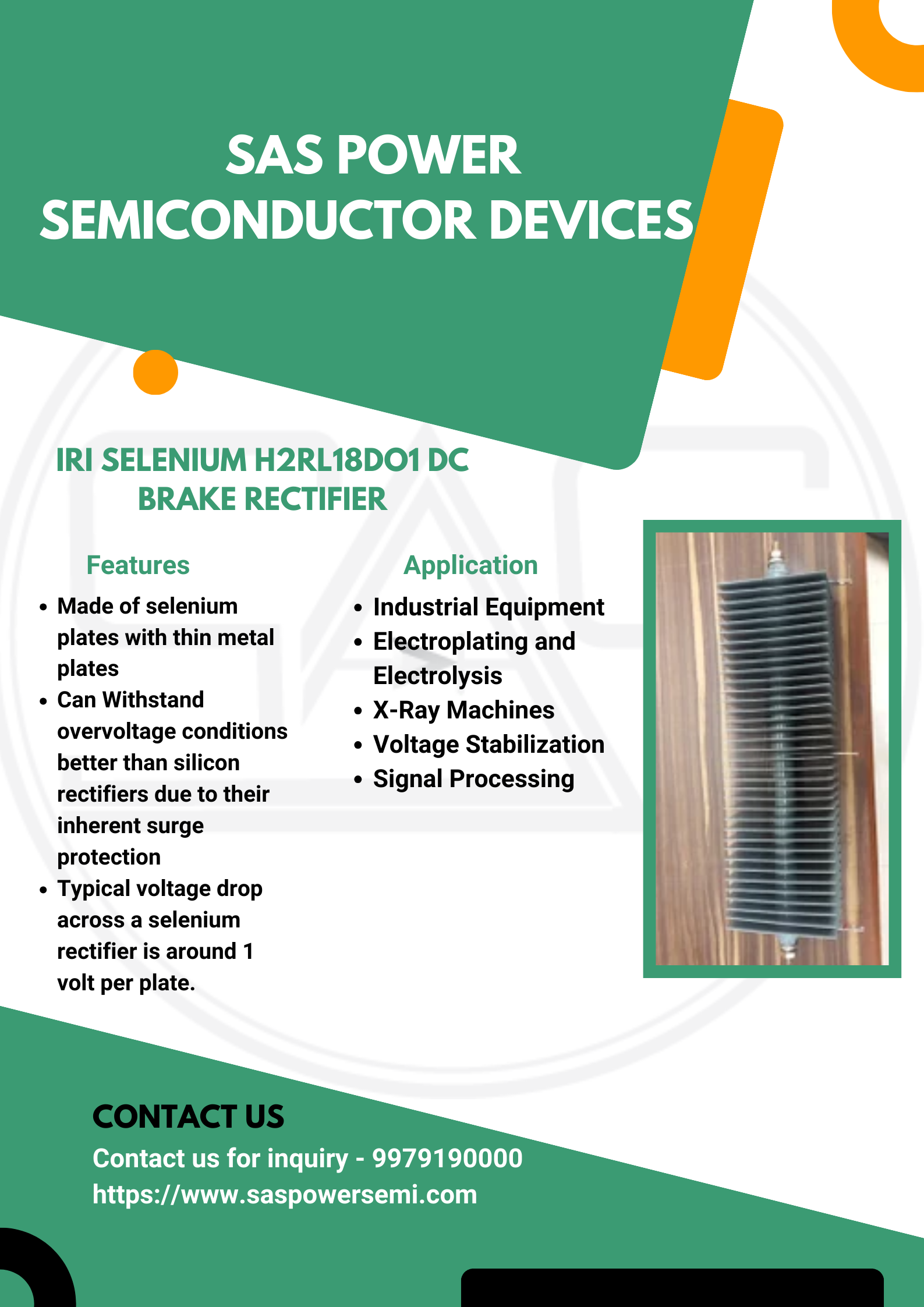

Selenium Plate Rectifiers: Features and Applications Features of Selenium Plate Rectifiers Construction: Made from stacked selenium plates with thin metal plates or aluminum as electrodes. Selenium acts as a semiconductor layer, often coated on an iron or aluminum base. High Durability: Can withstand overvoltage conditions better than silicon rectifiers due to their inherent surge protection. Current and Voltage Ratings: Typical voltage drop across a selenium rectifier is around 1 volt per plate. Suitable for low to moderate current applications. Temperature Tolerance: Operates efficiently at moderate temperatures but less suitable for high-temperature environments compared to modern silicon-based rectifiers. Non-Linear Characteristics: Selenium rectifiers exhibit non-linear voltage-current characteristics, making them useful in specific rectification and filtering tasks. Maintenance: Require minimal maintenance, though aging can lead to an increase in voltage drop and decrease in efficiency. Environmentally Sensitive: Selenium is toxic in high concentrations, so careful handling and disposal are necessary. Applications of Selenium Plate Rectifiers Industrial Equipment: Used in older motor control circuits, welding equipment, and battery chargers for DC power supply. Electroplating and Electrolysis: Provides a controlled DC supply for these processes. X-Ray Machines: Used in medical and industrial X-ray equipment due to their high reliability under surge conditions. Signal Processing: Previously used in low-frequency signal rectification in communication devices. Voltage Stabilization: Employed in older power conditioning equipment for voltage regulation. Advantages Built-in overvoltage protection due to their natural resistance to high voltage spikes. Robust and reliable in applications with moderate power requirements. Limitations Higher voltage drop and lower efficiency compared to modern silicon rectifiers. Larger and heavier, limiting use in compact devices. Gradual decline in performance with age, requiring periodic checks in critical applications. Modern advancements have largely replaced selenium rectifiers with silicon and silicon carbide rectifiers for their superior efficiency, compactness, and environmental safety. However, selenium rectifiers remain a viable choice in legacy systems or specific industrial contexts requiring robust overvoltage protection.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-12-14T06:03:03

Selenium Plate Rectifiers: Features and Applications Features of Selenium Plate Rectifiers Construction: Made from stacked selenium plates with thin metal plates or aluminum as electrodes. Selenium acts as a semiconductor layer, often coated on an iron or aluminum base. High Durability: Can withstand overvoltage conditions better than silicon rectifiers due to their inherent surge protection. Current and Voltage Ratings: Typical voltage drop across a selenium rectifier is around 1 volt per plate. Suitable for low to moderate current applications. Temperature Tolerance: Operates efficiently at moderate temperatures but less suitable for high-temperature environments compared to modern silicon-based rectifiers. Non-Linear Characteristics: Selenium rectifiers exhibit non-linear voltage-current characteristics, making them useful in specific rectification and filtering tasks. Maintenance: Require minimal maintenance, though aging can lead to an increase in voltage drop and decrease in efficiency. Environmentally Sensitive: Selenium is toxic in high concentrations, so careful handling and disposal are necessary. Applications of Selenium Plate Rectifiers Industrial Equipment: Used in older motor control circuits, welding equipment, and battery chargers for DC power supply. Electroplating and Electrolysis: Provides a controlled DC supply for these processes. X-Ray Machines: Used in medical and industrial X-ray equipment due to their high reliability under surge conditions. Signal Processing: Previously used in low-frequency signal rectification in communication devices. Voltage Stabilization: Employed in older power conditioning equipment for voltage regulation. Advantages Built-in overvoltage protection due to their natural resistance to high voltage spikes. Robust and reliable in applications with moderate power requirements. Limitations Higher voltage drop and lower efficiency compared to modern silicon rectifiers. Larger and heavier, limiting use in compact devices. Gradual decline in performance with age, requiring periodic checks in critical applications. Modern advancements have largely replaced selenium rectifiers with silicon and silicon carbide rectifiers for their superior efficiency, compactness, and environmental safety. However, selenium rectifiers remain a viable choice in legacy systems or specific industrial contexts requiring robust overvoltage protection.

2024-12-14T06:03:03

Keywords

- 1 volt

- applications features

- plate suitable

- legacy systems

- viable choice

- environmental safety

- heavier limiting

- natural resistance

- high reliability

- battery chargers

- careful handling

- high concentrations

- voltage drop

- moderate temperatures

- semiconductor layer

- specific rectification

- selenium rectifier

- silicon carbide rectifiers

- silicon rectifiers due

- lowfrequency signal rectification

- selenium rectifiers remain

- electrodes selenium acts

- stacked selenium plates

- superior efficiency compactness

- lower efficiency compared

- processes xray machines

- controlled dc supply

- hightemperature environments compared

- withstand overvoltage conditions

- thin metal plates

Submit Your Enquiry